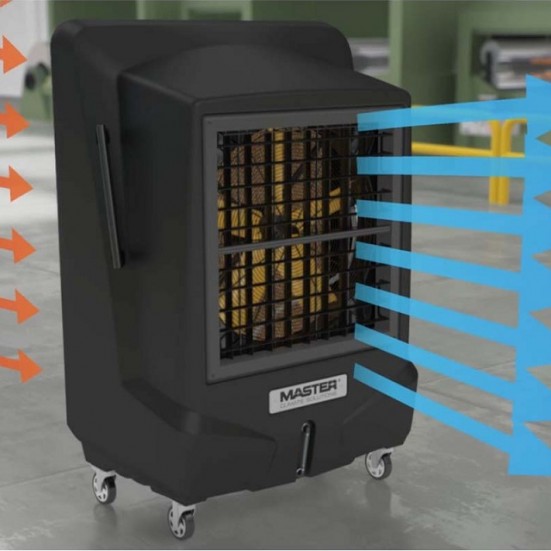

How does it work

The heart of the evaporative cooling system is the cooling pad where the water evaporates and the air passing through the pads is cooled. Evaporative cooling pads are manufactured from fluted cellulose sheets that are glued together. The material is chemically impregnated with special compounds to prevent rot and ensure a long service life and easy maintenance.

Evaporative cooling and humidity

A given volume of air at a certain temperature and pressure is capable of absorbing and holding a certain amount of water vapour. If that volume of air contains 50% of the moisture it is capable of holding, we say it is at 50% relative humidity. The hotter the day, the drier the air, the more cooling can be done by means of evaporation. In other words, the cooling effect is best when you need it most. Our evaporative coolers are developed to work well in high-humidity environments too, however, and will remain much more efficient than a simple fan that just circulates warm air. Our coolers will increase humidity by 2 to 5%, depending on temperature and humidity in the environment you want to cool. The slight increase is not noticeable in ventilated areas where the air produced by the unit is exhausted.

Features

- Efficient and durable spot cooler for industrial applications

- Quiet running even with large air flow

- Automatic swing function as standard

- Large water tank for longer operating hours

- Large, durable wheels with brakes allow easy movement

- Connect water hose or refill tank manually to offer comfort to your employees

- Corrosion-resistant plastic casing

- Air filter included to enable easy maintenance

- Remote control to easily adjust speed

- UV lamp, disinfecting the water

Benefts

- The use of air coolers strongly reduces the CO₂ impact compared to air-conditioners

- Clean air that reduces the risk of bacteria and virus

- No chemicals or refrigerants

- Low energy consumption

- Virtually maintenance-free equipment